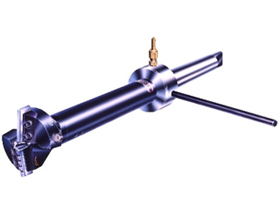

n the shrinking tooling system, a shrinking (grilled barrel) holder is heated (about 300 ° C.) in a short time (within 10 seconds) by a high frequency induction heating device to expand it, and the cutting tool of a carbide, high speed steel shank It is a touring system that is made of detachable net.

"BT Shank Regular Type" which exerts its power in rough machining and heavy cutting with abundant variations, "ST Shank Straight Type" for transforming the smallest cutting tool into long shank, "HSK Shank Regular Type , "High Frequency Induction Heating Device [Independent Type Automatic Type]", "Cooling Unit", and others.

Since the shrinking holder adopts integration, a stable runout system can be obtained, it is possible to realize high precision, high balance, high speed machining, high grasping force, high rigidity, long tool life and machined surface roughness It will be possible to improve.

Hard chuck designs the conditions required for tooling (rigidity, centripetality, operability, economy) comprehensively, so it is easy to harmonize all conditions with a high level and a reasonable tool layout It will be possible.

By adopting a ball screw mechanism, the small diameter hard chuck is 3 to 5 times tightening force as compared with the conventional one. Especially it withstands heavy cutting by cemented carbide blade, it is suitable for cavity processing of metal mold. It is easy to operate and detach the tool only by half turning the nut

Hard chuck designs the conditions required for tooling (rigidity, centripetality, operability, economy) comprehensively, so it is easy to harmonize all conditions with a high level and a reasonable tool layout It will be possible.

By adopting a ball screw mechanism, the small diameter hard chuck is 3 to 5 times tightening force as compared with the conventional one. Especially it withstands heavy cutting by cemented carbide blade, it is suitable for cavity processing of metal mold. It is easy to operate and detach the tool only by half turning the nut

n the shrinking tooling system, a shrinking (grilled barrel) holder is heated (about 300 ° C.) in a short time (within 10 seconds) by a high frequency induction heating device to expand it, and the cutting tool of a carbide, high speed steel shank It is a touring system that is made of detachable net.

"BT Shank Regular Type" which exerts its power in rough machining and heavy cutting with abundant variations, "ST Shank Straight Type" for transforming the smallest cutting tool into long shank, "HSK Shank Regular Type , "High Frequency Induction Heating Device [Independent Type Automatic Type]", "Cooling Unit", and others.

Since the shrinking holder adopts integration, a stable runout system can be obtained, it is possible to realize high precision, high balance, high speed machining, high grasping force, high rigidity, long tool life and machined surface roughness It will be possible to improve.

Hard chuck designs the conditions required for tooling (rigidity, centripetality, operability, economy) comprehensively, so it is easy to harmonize all conditions with a high level and a reasonable tool layout It will be possible.

By adopting a ball screw mechanism, the small diameter hard chuck is 3 to 5 times tightening force as compared with the conventional one. Especially it withstands heavy cutting by cemented carbide blade, it is suitable for cavity processing of metal mold. It is easy to operate and detach the tool only by half turning the nut

Hard chuck designs the conditions required for tooling (rigidity, centripetality, operability, economy) comprehensively, so it is easy to harmonize all conditions with a high level and a reasonable tool layout It will be possible.

By adopting a ball screw mechanism, the small diameter hard chuck is 3 to 5 times tightening force as compared with the conventional one. Especially it withstands heavy cutting by cemented carbide blade, it is suitable for cavity processing of metal mold. It is easy to operate and detach the tool only by half turning the nut